SMART DOG MININGTM

It

takes a smart dog to find hidden treasures

What Shall We Do With A Process Simulator?

What shall we do with a Process Simulator?

What shall we do with a Process Simulator?

What shall we do with a Process Simulator?

Early in the morning.

Quick question; by a show of hands, how many out there have a

process simulator or model of their plant?

How many ever use it beyond bringing it out now and again to

show people this wonder-full package that that you have to model

your operation?

Probably not many.

Next question, how many have a data historian to gather and manage

your process data?

Ever think of using the two together for process control?

Or even better using the expensive model as an example to

take your data historian tools to create an integrated plant model?

A key part of any engineer’s job is to figure out why things are not

working right. In

mining and mineral processing this can be a big part.

With the growth in big data this is supposedly easier,

because you have all that information.

But what does it mean!

When your plant is not running right and the process control system

seems to be making things work, figuring out why is important and

not figuring out can be expensive.

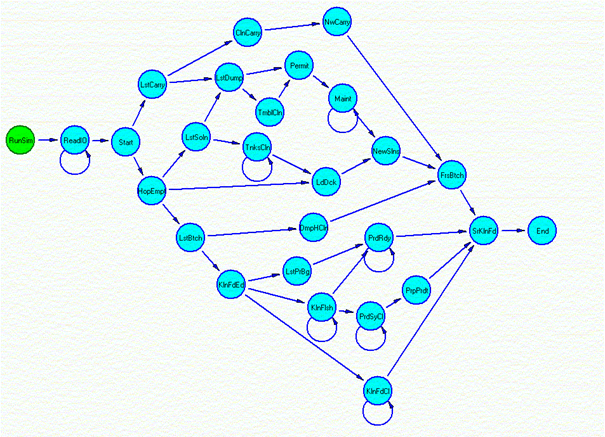

At some point, most mines have invested in a process simulation

model of the process, if at no other time, during the initial

design. This was

primarily used for preparing and balancing the flowsheet and doing

initial equipment sizing.

But it can also be used for checking a plants operation and

also predicting how the plant should operate under changing feed

conditions. And yes,

many of these models are large and complicated to run, they can be

used along with data historians to prepare simpler models of the

plant and then using the big data to predict what should have

happened.

Another use is to tie it in with the mine planning to predict what

various mining plans will do to plant control, and help being

prepared for what might happen.

So how, start with your simulator, and then take your historical (or

as some would say your hysterical) data and compare what should have

happened to what did happen.

Working forward and back the actual impacts can be determined

and then the model can be adjusted (or a new simpler model

prepared).

While the first couple of run troughs of this might be frustrating

and tedious, it will get easier like learning to ride a bicycle.

And you already have the bike (tools) so make use of them.

It will pay off.

o

40+ years’ experience in the mining industry with strong mineral

processing experience in precious metals, copper, industrial

minerals, coal, and phosphate

o

Operational experience in precious metals, coal, and phosphate plus

in petrochemicals.

o

Extensive experience performing studies and determining feasibility

in the US and international (United States, Canada, Mexico, Ecuador,

Columbia, Venezuela, Chile, China, India, Indonesia, and Greece).

o

E-mail:

info@smartdogmining.com