SMART DOG MININGTM

It

takes a smart dog to find hidden treasures

An Introduction to Flowing Film Concentration

Launderers, spirals and tables fall into the general class of

flowing film concentrators were the primary means of separation is a

flowing film combined with stratification. They utilize the

principal of flowing film separation, and combine this with bed

stratification to enhance recovery and increase capacity.

The actual separation mechanism varies by device, but the

general principal is having a feed stream a rate where the coarse

heavy particles settle to form a bed which then aids the

concentration of finer heavy particles.

The lighter particles are then carried away by the flow of

water. In the case of

spirals, centripetal forces aid in the separation.

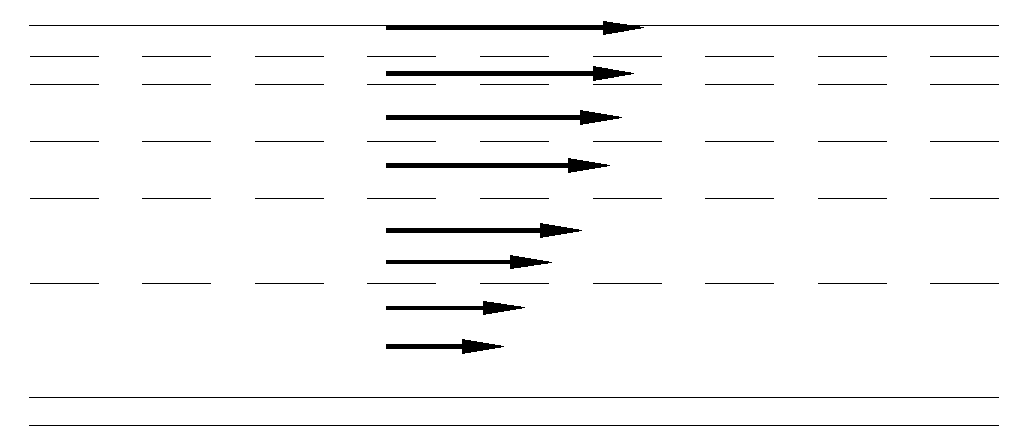

A flowing film in a gravity separation device introduces additional

forces, besides what is discussed in

An Introduction to Gravity

Concentration. The principal effect encountered comes from the

flow usually is not uniform from one place to another. As a result,

the shearing forces between adjacent layers of fluid produce

rotation and other effects on various particles.

Figure 1 – Velocity Distribution in Flowing Current

1.

Material of low density is carried faster than material of high

density.

2.

In mixtures of particles of a range of sizes coarse particles in

general are carried along the bottom of a stream faster than fine

ones.

Launders, in principle at least, represent an ideal method of

gravity concentration. In theory the bed density in a launder stream

increases from the top to the bottom, a desirable condition from the

standpoint of selectivity in the separation. The mobility decreases

with depth. If heavy material is withdrawn from the bottom of a

flowing stream, it is evident that it will at some time have passed

through a zone where the bed density is as high and the mobility as

low as practicable - condition already recognized as most desirable

in gravity concentration processes. Launders have the additional

advantage of requiring a minimum number of moving parts in their

construction.

1.

Large heavy particles.

2.

Large light particles and small heavy ones.

3.

Small light particles.

1.

Large light particles.

2.

Large heavy particles.

3.

Small heavy particles.

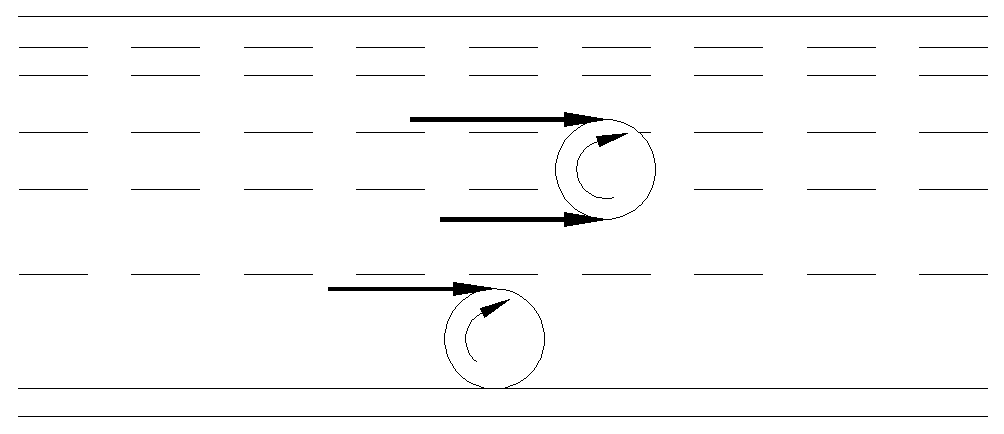

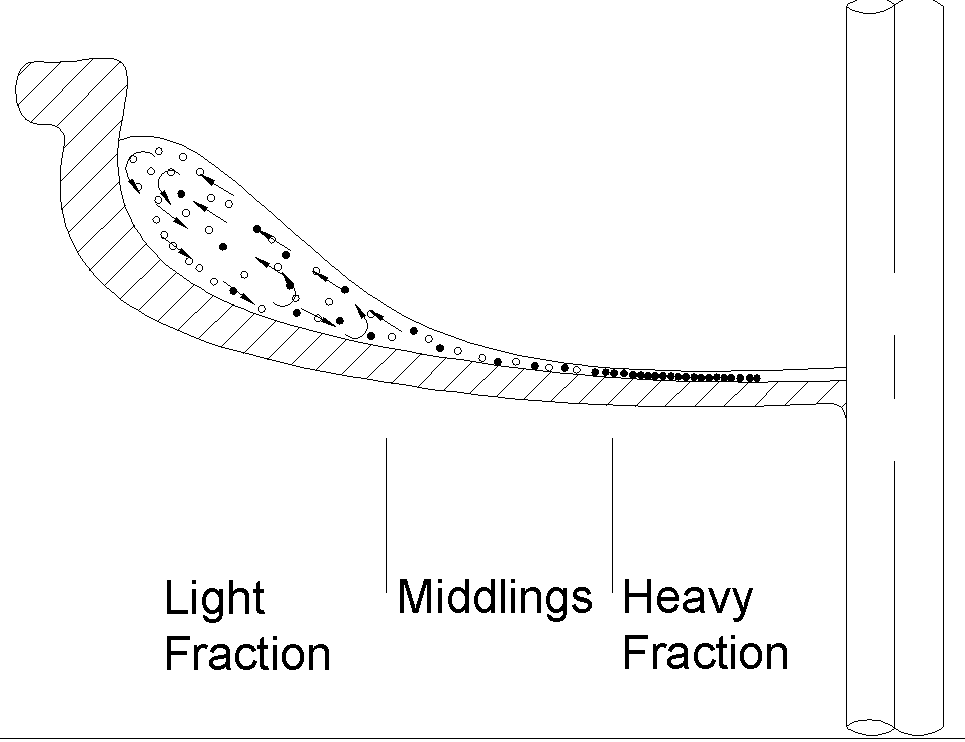

Spirals behave in general like a launderer, but with the addition of

centrifugal force (actually centrifugal force is an apparent force,

and the actual action is a "fictious force" caused by the inertia of

the particles and is a reaction to being confined by the outer

wall). This causes the

water to pile up on the outer edge with the lighter and finer

particles and the larger heavier particles to report to the inside.

A cross section of this action is shown in Figure 3.

Beyond this the actions are very similar to a launder.

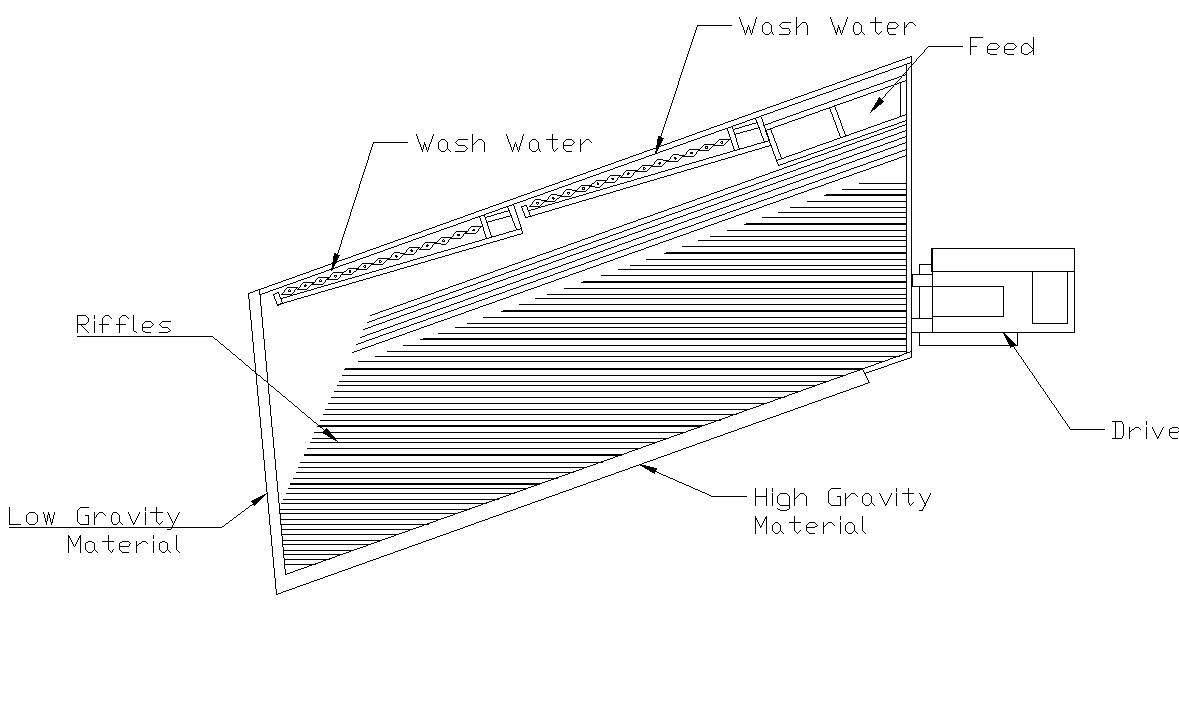

Concentrating tables (or shaking tables) introduce no principles of

separation that have not been considered. The sequence of hindered

settling followed by flowing stream selection is frequently utilized

by submitting material to be concentrated to a preliminary

classification. This is so common a practice that classification and

tabling has almost come to be recognized as a unitary process.

Figure 4 – Table

A theoretical objection to shaking tables is found in the fact that

mobility is imparted to the bed of material from beneath, with the

result that a zone of low bed density will be found immediately

adjacent to the surface. The separation is thus not as sharp as

could be desired at any one place. In effect, however, the

separation occurring between any two riffles is supplemented by the

re-treatment between the adjacent pair and the large number of

successive separations produces an acceptable end result.

In discussing the mechanics of hindered settling (in

An Introduction to Gravity

Concentration), nothing was said about the nature of the fluid

beyond the fact that it possessed viscosity and was capable of

exerting a force against particles moving relative to it. In air

tables the fluid in question has the property of being compressible.

This property in itself introduces no new forces into the behavior

of a bed of particles being separated. The principles are the same.

Hindered settling occurs in the same way as though the fluid were

incompressible. When operating with deep beds of material, however,

the air in the lower portion is under the pressure of the bed and

undergoes considerable change in volume in rising to the top.

Frequently this causes geysering in an improperly operating device

and is overcome by maintaining the bed in a state of partial

mobility through shaking, flowing, or other movements.

o

40+

years’ experience in the mining industry with strong mineral

processing experience in Precious metals, copper, industrial

minerals, coal, and phosphate

o

Operational experience in precious metals, coal, and phosphate plus

in petrochemicals.

o

Extensive experience studies and feasibility in the US and

international (United States, Canada, Mexico, Ecuador, Columbia,

Venezuela, Chile, China, India, Indonesia, and Greece).