SMART DOG MININGTM

It

takes a smart dog to find hidden treasures

Introduction to Dry Mineral Processing

A major issue in the world, and directly

effecting the mining industry is water or rather lack of water.

Rivers are running dry causing economic impacts and

humanitarian issues in many parts of the world.

Many, say most, mining and mineral processing operations

require water. Even

with best practices water scarcity is becoming a problem.

An

alternative is dry mineral processing.

This falls into two general categories: sorting and pneumatic

or air separation.

SORTING

One of the earliest, if not the earliest,

methods of mineral processing was sorting.

This made use of the difference in color, luster, or similar

property of one mineral from another.

This (along with gravity) remained the main method of

concentration until the later parts of the 19th century (and for

some minerals well into the 20th), primarily by doing hand sorting.

Even today hand sorting is often the final stage for small

artisanal mining and prospecting (selecting diamonds by eye and

picking gold from the pan).

Today sorting has also grown beyond this and

expanded to become commercial operations using how minerals react to

electromagnetism.

Electromagnetism has three properties all of which are used in

mineral processing: electric fields, magnetic fields, and

electromagnetic radiation (light).

Electrical Fields

Some minerals are relatively good conductors,

while others are relatively poor conductors of electricity.

This can be used to separate them. Most of the sulphide

minerals and most metals are, to some extent, conductors of

electricity, while the gangue minerals are generally poor

conductors. If ore particles

are brought into contact with an electrode containing a charge, the

better conductors become similarly charged and are repelled, in the

same way that pith balls would be under like conditions, while the

poorer conductors are not repelled or at least not as far.

Magnetic Fields

Attraction to a magnet is quite strong in some

minerals and metals; particularly magnetite, some forms of

pyrrhotite, cast iron, wrought iron, steel, nickel, and cobalt.

Other minerals, such as franklinite, chromite, or iron-bearing

sphalerite, garnet, etc., have very weak magnetism. Still others,

such as quartz, calcite, gypsum, feldspar, etc., exhibit no

attraction at all. This

property may be used to separate the magnetic from the non-magnetic.

Electromagnetic

Radiation

Under the stimulation of electrical magnetic

radiation, some minerals have distinctive optical properties.

The easiest to observe are color and luster which was (and

is) used in hand picking and optical sorting.

Slight differences in color

or in luster - for instance, the brass yellow of chalcopyrite, the

pale yellow of pyrite, the vitreous luster of quartz, the resinous

of sphalerite, the adamantine of diamond, the dull of chalk, and the

pearly of talc can furnish aids in hand picking and can be used for

optical sorting.

Further on in the spectrum particular under ultra-violet or even on

to x-rays, mineral fluorescence is used to sort.

Sorting as a Process

Sorting, particularly mechanized sorting,

requires the material to be between 1 mm and 20 microns in particle

size, and in feed rates of 150 tons per hour or less.

For sorting to be effective, and its major limitation, is

that the ore and the waste material must be well liberated in the

feed to the sorter (that is into practically discrete particles of

ore and waste). The larger the liberation size the more likely

sorting is to be cost effective.

Picking the correct ore sorting equipment for

an operation is important and often special machine features are

developed for an individual application.

As with any process, and more so than some, good sorter

performance requires extensive test work.

Often using prototype or preferably on production model

sorting machines at close to design tonnages and conditions as

possible.

If set-up and used properly, a high grade

concentrate can be produced, but recovery may suffer due to blocked

or locked particles.

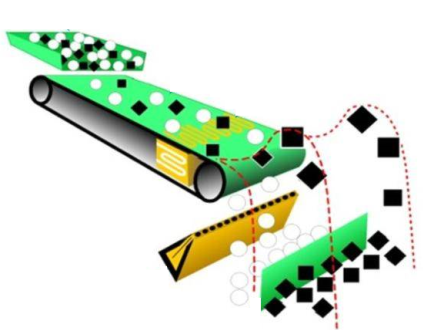

PNEUMATIC

CONCENTRATORS

Pneumatic

concentrators are those in which a gas, invariably air, is used to

effect differential movement of particles of different specific

gravities. They parallel the water-gravity concentrators In that

beds, quicksands, and the direct impulse of air on feed particles

are all utilized.

Bed-Type

Pneumatic Concentrators

In

settling rates of

particles in a pulsated bed of which they themselves are parts. The

group includes

all of the

pneumatic machines best known and most used. The essential elements

in all are a porous supporting

surface for a mass of grains; an air supply flowing upward through

the supporting surface and thence through the interstices of the

mass of

grains, means to

produce flow of the mass of grains and to constrain layers at

different vertical

depths therein to

move in different directions to different discharge points. These

are the essential elements

of a

water jig, except for the difference in interstitial medium.

The kind of stratification effected, with large, heavy

material of a given specific gravity at the bottom of the layer of

that material, is the same in both machines; the responses to

controls are, of course, also the same.

In other words, these apparatus, though having the general

form and appearance of shaking tables used for water-gravity

concentration, and

called pneumatic tables,

are actually pneumatic jigs.

Pneumatic

Quicksand

Blowing

Pneumatic

Gravity Equipment

Dry Washer (after West)

Air Table (after Forsberg’s

Inc.)

Air Jig (after Weitkaemper & Wotruba)

o

40+ years’ experience in the mining industry with strong mineral

processing experience in precious metals, copper, industrial

minerals, coal, and phosphate

o

Operational experience in precious metals, coal, and phosphate plus

in petrochemicals.

o

Extensive experience performing studies and determining feasibility

in the US and international (United States, Canada, Mexico, Ecuador,

Columbia, Venezuela, Chile, China, India, Indonesia, and Greece).

o

E-mail:

info@smartdogmining.com